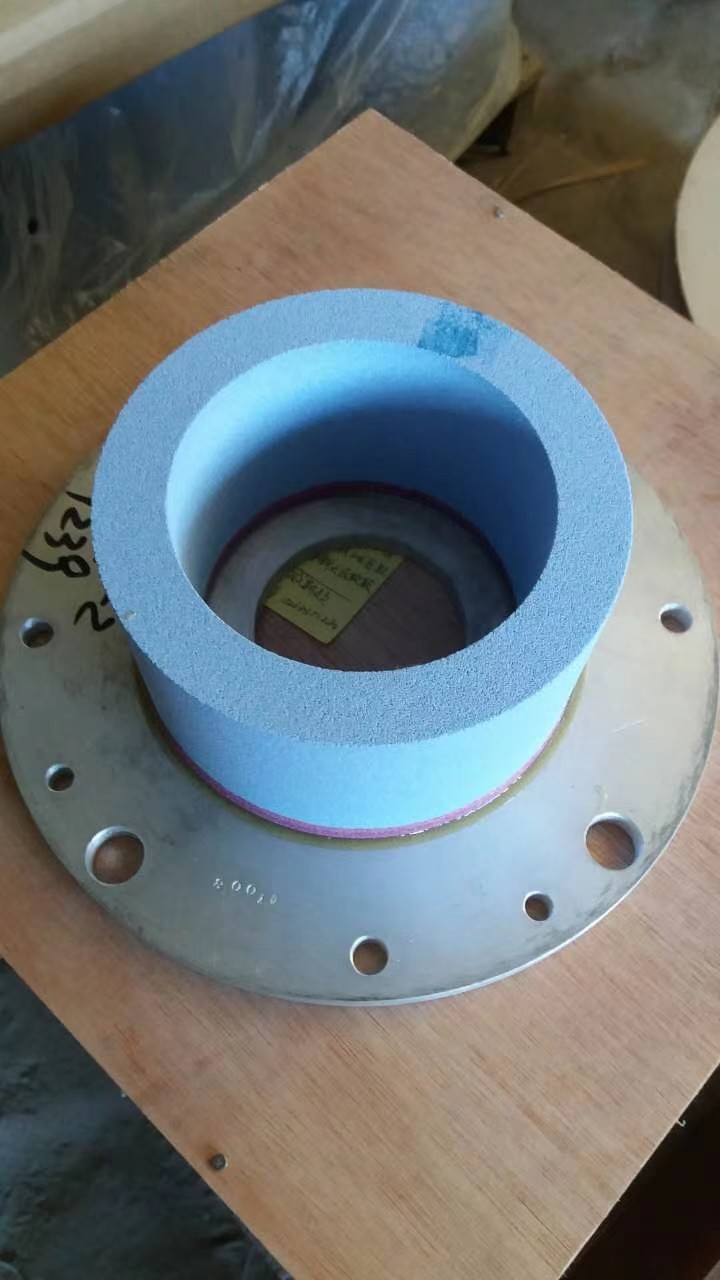

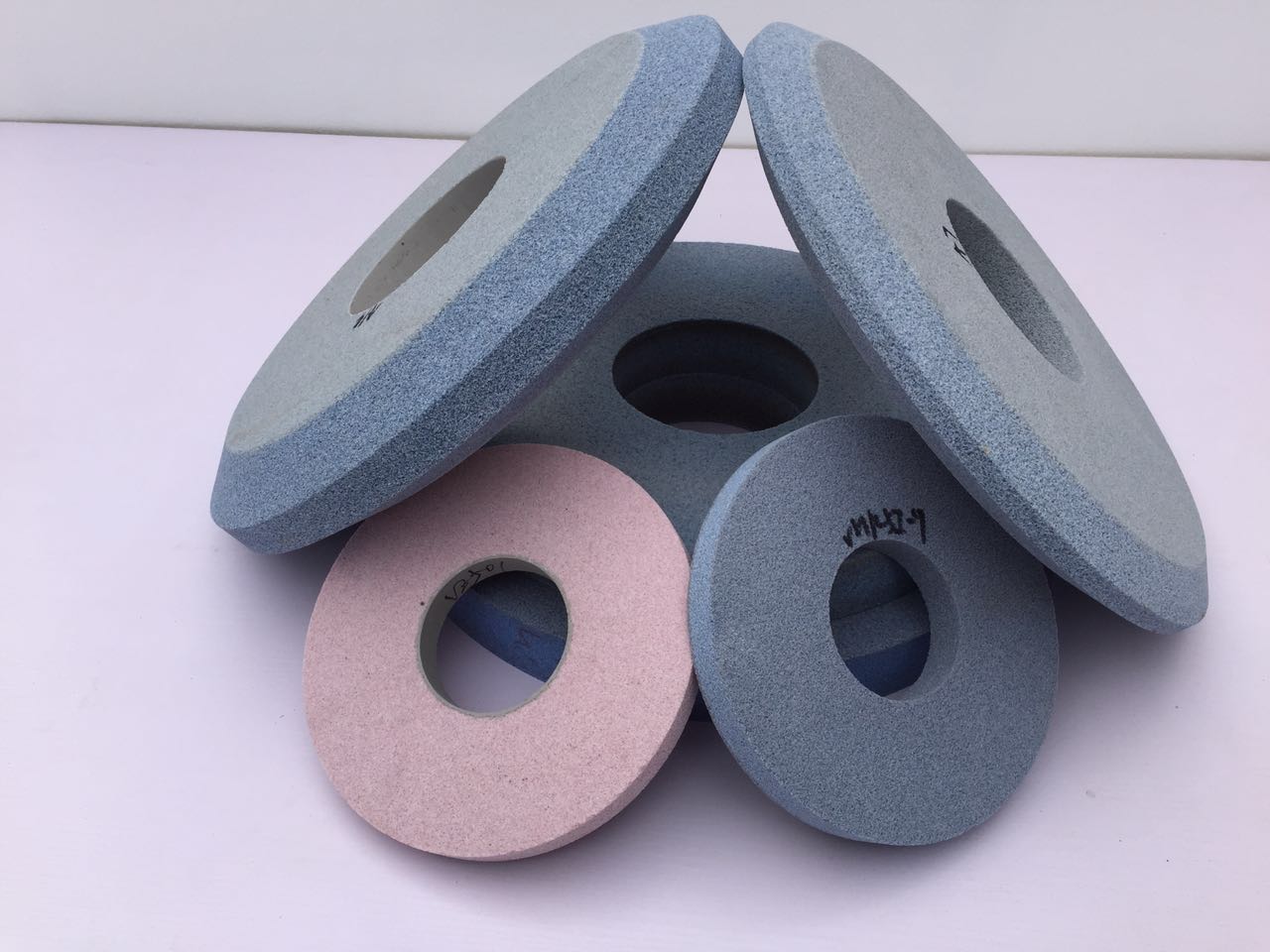

螺旋伞齿磨砂轮 Spiral Bevel Gear Grinding Wheels

螺旋伞齿磨砂轮

基本性能简介

公司生产的螺旋伞齿磨专用砂轮所使用的标准材质为5GW(等效于5SG),具备良好的锋利度和形状保持能力,适用于格里森、克林贝格、哈量凯帅、中大创远等设备厂家生产的各型号螺旋伞齿磨床。完全可按 Norton公司同类产品的使用参数使用。

Norton公司同类产品的使用参数使用。

规格代码 | 格里森代码 | 标准规格型号 | 砂轮参数 |

W35 | 66281235 | 104×86×69 | 5GW 70 J 7V 35m/s |

W36 | 66281236 | 117×86×81 | 5GW 70 J 7V 35m/s |

W37 | 66281237 | 132×86×91 | 5GW 70J 7V 35m/s |

W38 | 66281238 | 145×86×104 | 5GW 70 J 7V 35m/s |

W39 | 66281239 | 160×98×119 | 5GW 70 J 7V 35m/s |

W40 | 66281240 | 178×98×124 | 5GW 70 J 7V 35m/s |

W41 | 66281241 | 196×98×142 | 5GW 70 J 7V 35m/s |

W42 | 66281242 | 213×98×160 | 50W 70 J 7V 35m/s |

W43 | 66281243 | 234×98×180 | 50W 70 J 7V 35m/s |

W44 | 68281244 | 254×98×193 | SGW 70 J 7V 35m/s |

W45 | 66281245 | 274×98×213 | 5GW 70J 7V 35m/s |

W46 | 66281246 | 295×98×234 | 5GW 70 J 7V 35m/s |

W47 | 66281247 | 312×98×251 | 5GW 70J 7V 35m/s |

W48 | 66281248 | 330×98×269 | 5GW70J 7V 35m/s |

W49 | 66281249 | 351×98×284 | 5GW 70 J 7V 35m/s |

W50 | 66281250 | 366×98×297 | 5GW 70 J 7V 35m/s |

W51 | 68281251 | 386×98×312 | 5GW 70 J 7V 35m/s |

W52 | 68261252 | 406×98×325 | 5GW 70 J 7V 35m/s |

W53 | 66281253 | 427×98×345 | 5GW 70 J 7V 35m/s |

W54 | 66281254 | 442×98×361 | 5GW 70 J 7V 35m/s |

W55 | 66281255 | 457×98×376 | 50W 70 J 7V 35m/s |

W56 | 66281256 | 472×98×391 | 5GW 70 J 7V 35m/s |

W57 | 66281257 | 495×98×404 | 5GW 70 J 7V 35m/s |

W58 | 66281258 | 521×98×429 | 5GW 70 J 7V 35m/s |

W59 | 66281259 | 541×98×450 | 5GW 70 J 7V 35m/s |

W60 | 66281260 | 564×98×472 | 5GW 70 J 7V 35m/s |

W81 | 66281281 | 182×98×118 | 5GW 70 J 7V 35m/s |

W82 | 66281282 | 217×98×154 | 5GW 70 J 7V 35m/s |

W83 | 66281283 | 258×98×187 | 5GW 70 J 7V 35m/s |

W84 | 66281284 | 297×98×226 | 5GW 70 J 7V 35m/s |

W85 | 66281285 | 335×198×259 | 5GW 70 J 7V 35m/s |

W86 | 66281286 | 396×98×305 | 5GW 70 J 7V 35m/s |

W87 | 66281287 | 452×98×348 | 5GW 70 J 7V 35m/s |

W88 | 66281288 | 508×98×394 | 5GW 70 J 7V 35m/s |

订货、使用及存储注意事项

由于此类砂验结构的特殊性,请严施检设备厂家要求的使用条件使用,尤其是磨齿机的工作环境温度,对砂轮的装卡精度和使用安全性影响较大,请把砂轮存放于磨齿机使用环境温度相当的场所。

对于磨削常规材质齿轮常规精度要求的订货,自订单产生之日起7-10个工作目即可发出,请根据自身生产计划所需安排订货,不必有过多库存占用资金。

公司可定制磨削军品等特殊材质、特珠要求齿轮的专用砂轮,形成稳定供需关系系后亦可在订单产生7-10个工作日内发出货物。

Spiral Bevel Gear Grinding Wheels

Performance:

Material: 5GW (equivalent to 5SG) with excellent sharpness and shape retention.

Compatible with machines from Gleason, Klingelnberg, Hofler, and others.

Matches Norton’s technical parameters.

Specifications:

Specification Code | Gleason Code | Standard Specification Model | Grinding Wheel Parameters |

W35 | 66281235 | 104×86×69 | 5GW 70 J 7V 35m/s |

W36 | 66281236 | 117×86×81 | 5GW 70 J 7V 35m/s |

W37 | 66281237 | 132×86×91 | 5GW 70J 7V 35m/s |

W38 | 66281238 | 145×86×104 | 5GW 70 J 7V 35m/s |

W39 | 66281239 | 160×98×119 | 5GW 70 J 7V 35m/s |

W40 | 66281240 | 178×98×124 | 5GW 70 J 7V 35m/s |

W41 | 66281241 | 196×98×142 | 5GW 70 J 7V 35m/s |

W42 | 66281242 | 213×98×160 | 50W 70 J 7V 35m/s |

W43 | 66281243 | 234×98×180 | 50W 70 J 7V 35m/s |

W44 | 68281244 | 254×98×193 | SGW 70 J 7V 35m/s |

W45 | 66281245 | 274×98×213 | 5GW 70J 7V 35m/s |

W46 | 66281246 | 295×98×234 | 5GW 70 J 7V 35m/s |

W47 | 66281247 | 312×98×251 | 5GW 70J 7V 35m/s |

W48 | 66281248 | 330×98×269 | 5GW70J 7V 35m/s |

W49 | 66281249 | 351×98×284 | 5GW 70 J 7V 35m/s |

W50 | 66281250 | 366×98×297 | 5GW 70 J 7V 35m/s |

W51 | 68281251 | 386×98×312 | 5GW 70 J 7V 35m/s |

W52 | 68261252 | 406×98×325 | 5GW 70 J 7V 35m/s |

W53 | 66281253 | 427×98×345 | 5GW 70 J 7V 35m/s |

W54 | 66281254 | 442×98×361 | 5GW 70 J 7V 35m/s |

W55 | 66281255 | 457×98×376 | 50W 70 J 7V 35m/s |

W56 | 66281256 | 472×98×391 | 5GW 70 J 7V 35m/s |

W57 | 66281257 | 495×98×404 | 5GW 70 J 7V 35m/s |

W58 | 66281258 | 521×98×429 | 5GW 70 J 7V 35m/s |

W59 | 66281259 | 541×98×450 | 5GW 70 J 7V 35m/s |

W60 | 66281260 | 564×98×472 | 5GW 70 J 7V 35m/s |

W81 | 66281281 | 182×98×118 | 5GW 70 J 7V 35m/s |

W82 | 66281282 | 217×98×154 | 5GW 70 J 7V 35m/s |

W83 | 66281283 | 258×98×187 | 5GW 70 J 7V 35m/s |

W84 | 66281284 | 297×98×226 | 5GW 70 J 7V 35m/s |

W85 | 66281285 | 335×198×259 | 5GW 70 J 7V 35m/s |

W86 | 66281286 | 396×98×305 | 5GW 70 J 7V 35m/s |

W87 | 66281287 | 452×98×348 | 5GW 70 J 7V 35m/s |

W88 | 66281288 | 508×98×394 | 5GW 70 J 7V 35m/s |

Ordering, Usage, and Storage Guidelines

Due to the unique structure of this type of grinding wheel, strictly follow the usage conditions specified by the equipment manufacturer, particularly the operating ambient temperature of the gear grinding machine. Temperature significantly impacts the clamping accuracy and safety of the grinding wheel. Store the grinding wheel in an environment with a temperature equivalent to that of the gear grinding machine’s operating conditions.

For orders involving grinding wheels for conventional materials and standard precision requirements, products will be shipped within 7-10 working days from the order date. Please plan your orders based on production needs to avoid excessive inventory and capital tie-up.

Our company offers customized grinding wheels for special materials (e.g., military-grade) or unique requirements (e.g., high-precision gears). Once a stable supply relationship is establi

在线订购

栏目导航

联系我们

联系人: 张先生 Kevin

电话: 0086-17778938919

微信:0086-17778938919

地址: 中国陕西省西安市朱雀路78号 No.78, Zhuque Road, Xi'an, China, 710061