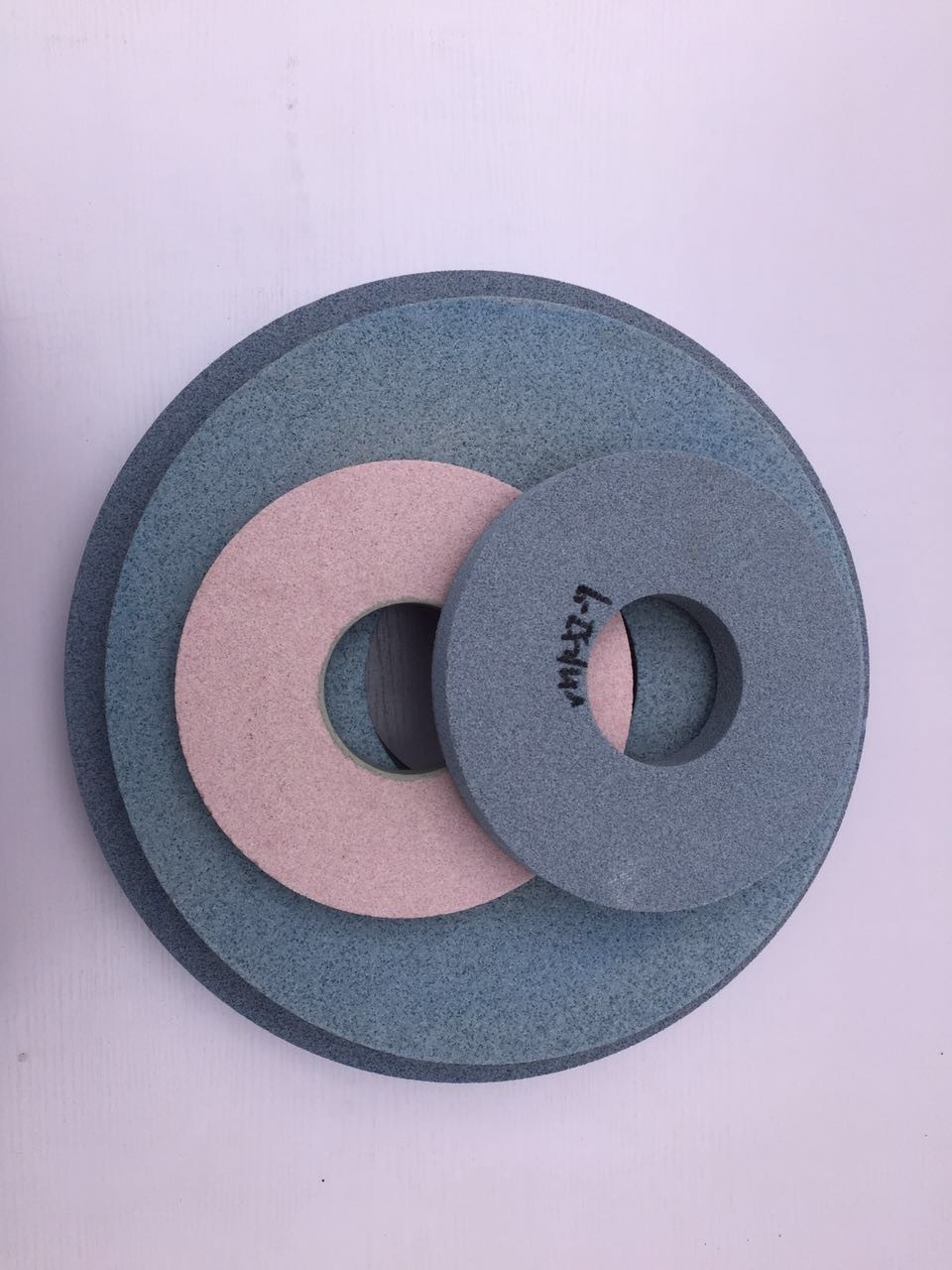

圆柱齿轮成型磨砂轮 Cylindrical Gear Form Grinding Wheels

圆柱齿轮成型磨砂轮

性能简介

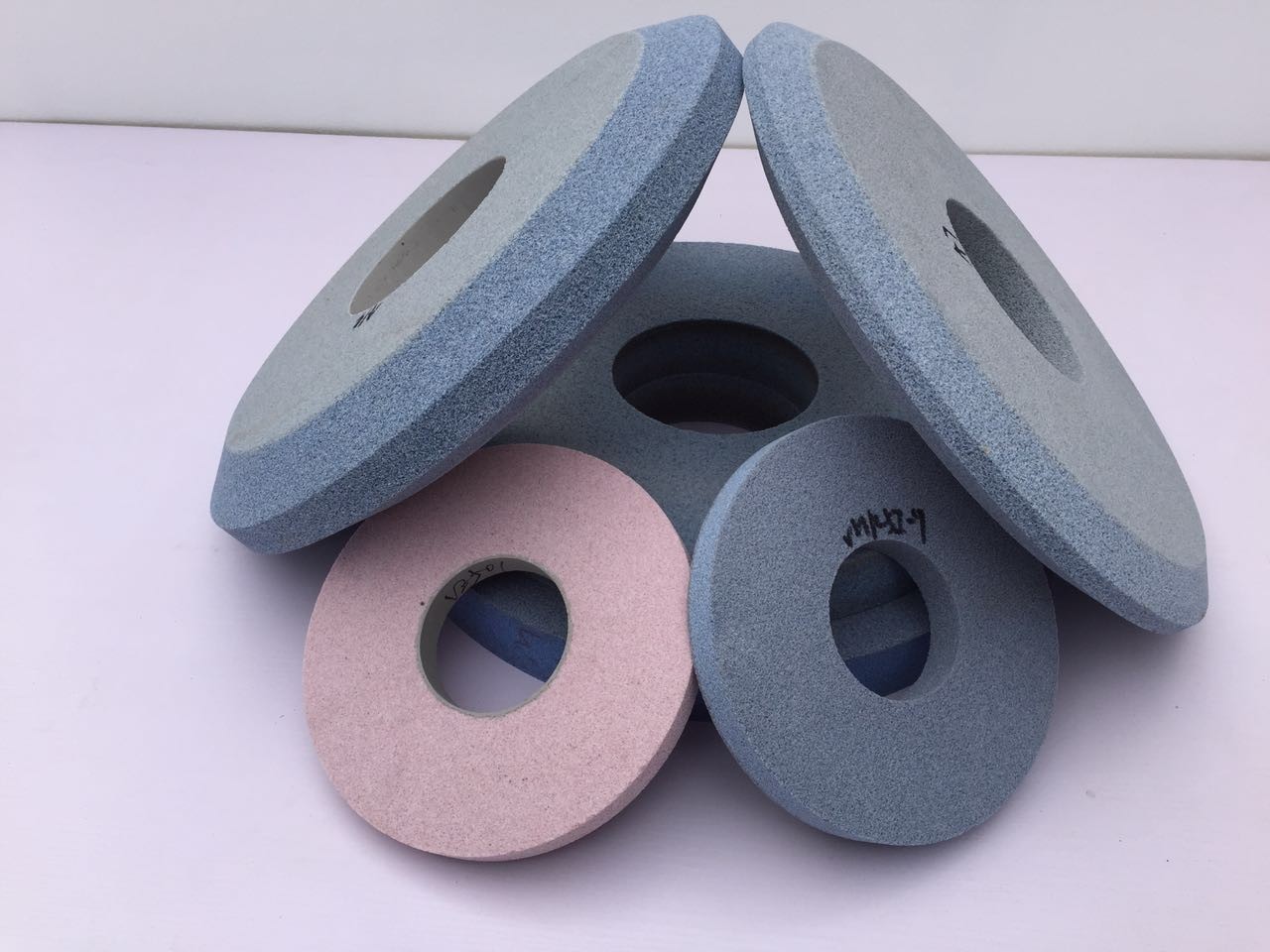

公司自主研发生产的圆柱齿轮成型磨专用砂轮广泛适用于尼尔斯、霍夫勒、普法特、桑普塔斯力、秦川等各系列数控磨床,砂轮主要性能参数及适用范围如下:

1、SA 46#一100# G-J10V 50m/s:此产品主要适用于常规材质齿轮(20CrMnTi)较低精度要求的加工,其特点是砂轮单价较低,资金占用量少,宏观齿面光洁度(亮度)较好。缺点是磨削效率较低、修整量大、防烧伤能力较差、齿面硬度衰失倾向较大,综合性价比低。

2、3GW 46#-100# G-J 10V 50m/s:此产品材质等同于3SG。是目前用量最大的产品,广泛应用于各种主要材质齿轮的磨削加工,和“SA46#-100# G-J10V 50m/s”类产品比较除去资金占用量略大、宏观光洁度(亮度)略低外,其他各项指标都有较大优势,尤其是在合理选择使用参数前提下,其性价比优势更加明显。

3、5GW 46#-100#G-J 10V 50m/s:此产品材质等同于5SG。其主要用途是磨削加工难磨齿轮材质如17CrNiMo6-----其绝大部分指标和“3GW 46#一100# G-J 10V 50m/s”相比有明显的优势,尤其是抗粘附防烧伤能力及生产效率方面。

4、请根据需求合理选用匹配参数,最常用粒度为60#硬度。

5、此类产品在合理匹配参数前提下同样适用于压缩机螺杆加工。

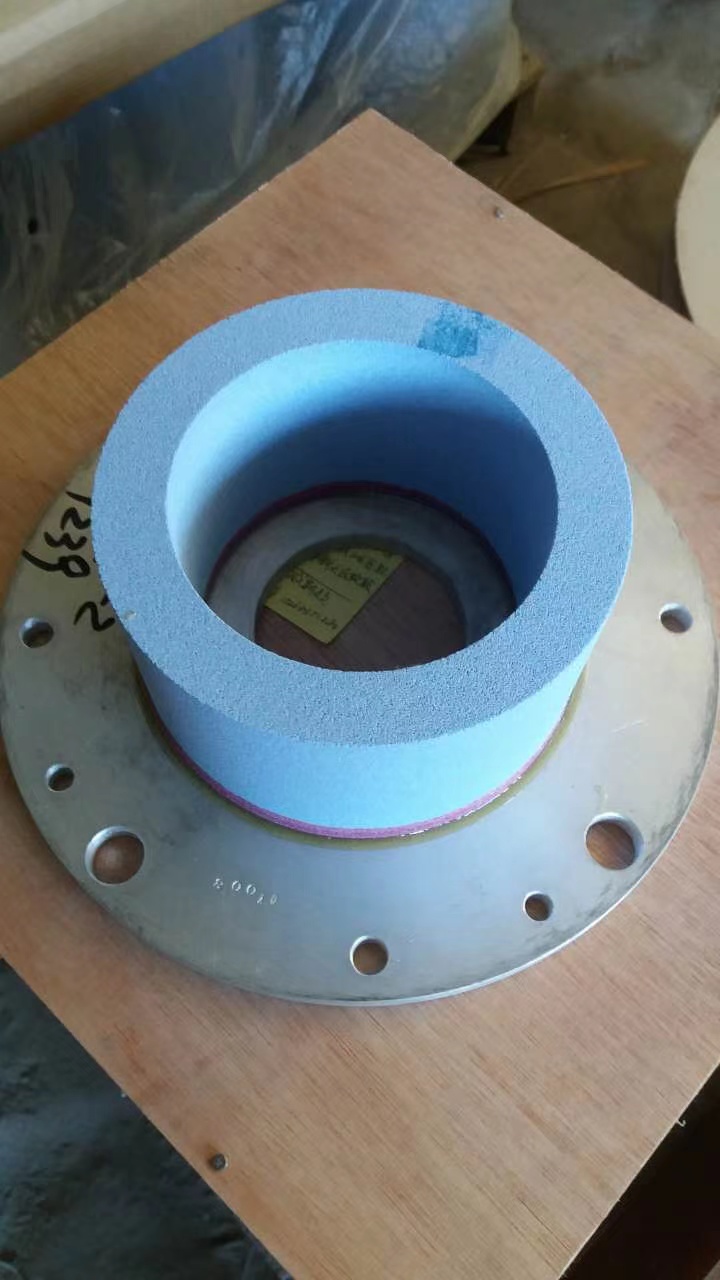

产品规格及机床型号

300*T*127

T=15、20、25、32、40、45、50、63……Gleason Hofier Niles等

350*T*127

T=15、20、25、32、40、45、50、63、70……Gleason Hofler Niles等

400*T*127

T=15、20、25、32、40、45、50、63、70、80……Gleason Hofler Niles等

400*T*160

T=15、20、25、32、40、45、50、63、70、80……Hofler 秦川等

450'T*160

T=15、20、25、32、40、45、50、63、70、80、90……Gleason Hofler Niles 等

500*T*160

T=15、20、25、32、40、45、50、63、70、80、90、100、110……Gleason Hofler Niles等

200*T*75

T=10、12、15、20、25…… 秦川等

订货注意事项

常规产品可在订单产生后10个工作日内发货,特殊订制产品形成稳定供需关系后也可在10个工作日内发货,请根据需求合理订货以减少资金占用。

建议根据齿轮模数、压力角等参数选择修形好的砂轮,以减少滚轮消耗、提高功效,确保使用性能和安全性。

Cylindrical Gear Form Grinding Wheels

Performance Introduction

Our independently developed and manufactured cylindrical gear form grinding wheels are widely applicable to various CNC grinding machines, including Niles, Höfler, Pfauter, Samputensili, Qinchuan, and others. The main performance parameters and application ranges are as follows:

SA 46#–100# G-J 10V 50 m/s:

Application: Suitable for grinding conventional material gears (e.g., 20CrMnTi) with lower precision requirements.

Advantages: Low unit cost, minimal capital occupancy, and good macro surface finish (brightness).

Disadvantages: Lower grinding efficiency, higher dressing frequency, poor anti-burn capability, and significant surface hardness loss. Overall cost-performance ratio is low.

3GW 46#–100# G-J 10V 50 m/s:

Material: Equivalent to 3SG.

Application: The most widely used product, suitable for grinding various gear materials.

Advantages: Compared to SA 46#–100# G-J 10V 50 m/s, it offers significant improvements in most performance indicators, except for slightly higher capital occupancy and slightly lower macro surface finish (brightness). When used with optimal parameters, its cost-performance ratio is highly competitive.

5GW 46#–100# G-J 10V 50 m/s:

Material: Equivalent to 5SG.

Application: Specifically designed for grinding difficult-to-machine gear materials, such as 17CrNiMo6.

Advantages: Compared to 3GW 46#–100# G-J 10V 50 m/s, it offers superior performance in most indicators, especially in anti-adhesion, anti-burn capability, and production efficiency.

Parameter Selection:

Choose the appropriate parameters based on your requirements. The most commonly used grit size is 60# with hardness.

Additional Application:

With proper parameter matching, these products are also suitable for compressor screw processing.

By selecting the right grinding wheel and parameters, you can achieve optimal grinding performance and efficiency. For further customization or technical support, please contact our team.

Product Specifications and Applicable Machine Models

Grinding Wheel Size | Applicable Machine Models |

300T127 (T=15, 20, 25, 32, 40, 45, 50, 63, ...) | Gleason, Höfler, Niles, etc. |

350T127 (T=15, 20, 25, 32, 40, 45, 50, 63, 70, ...) | Gleason, Höfler, Niles, etc. |

400T127 (T=15, 20, 25, 32, 40, 45, 50, 63, 70, 80, ...) | Gleason, Höfler, Niles, etc. |

400T160 (T=15, 20, 25, 32, 40, 45, 50, 63, 70, 80, ...) | Höfler, Qinchuan, etc. |

450T160 (T=15, 20, 25, 32, 40, 45, 50, 63, 70, 80, 90, ...) | Gleason, Höfler, Niles, etc. |

500T160 (T=15, 20, 25, 32, 40, 45, 50, 63, 70, 80, 90, 100, 110, ...) | Gleason, Höfler, Niles, etc. |

200T75 (T=10, 12, 15, 20, 25, ...) | Qinchuan, etc. |

Ordering Guidelines

Delivery Time:

Standard products can be shipped within 10 working days after the order is confirmed.

For special customized products, once a stable supply-demand relationship is established, they can also be shipped within 10 working days.

Please plan your orders according to your needs to minimize capital occupancy.

Product Selection:

It is recommended to select pre-dressed grinding wheels based on gear parameters such as module and pressure angle. This helps reduce roller consumption, improve efficiency, and ensure optimal performance and safety.

By following these guidelines, you can optimize your ordering process and ensure efficient and safe use of the grinding wheels. For further assistance or customization needs, please contact our team.

在线订购

栏目导航

联系我们

联系人: 张先生 Kevin

电话: 0086-17778938919

微信:0086-17778938919

地址: 中国陕西省西安市朱雀路78号 No.78, Zhuque Road, Xi'an, China, 710061